RNLAF C-130H upgrade programme

RNLAF C-130H upgrade programme The recovery and upgrade of two C-130s for the Royal Netherlands Air …

Marshall is proud to work with global OEMs and fleet operators to extend the mission capability and longevity of their aircraft, while self-certifying our own work.

Whether we’re replacing the centre wing box on a C-130J Super Hercules or increasing the operating range of Boeing’s P-8A Poseidon patrol aircraft, capability enhancement is at the core of what Marshall does.

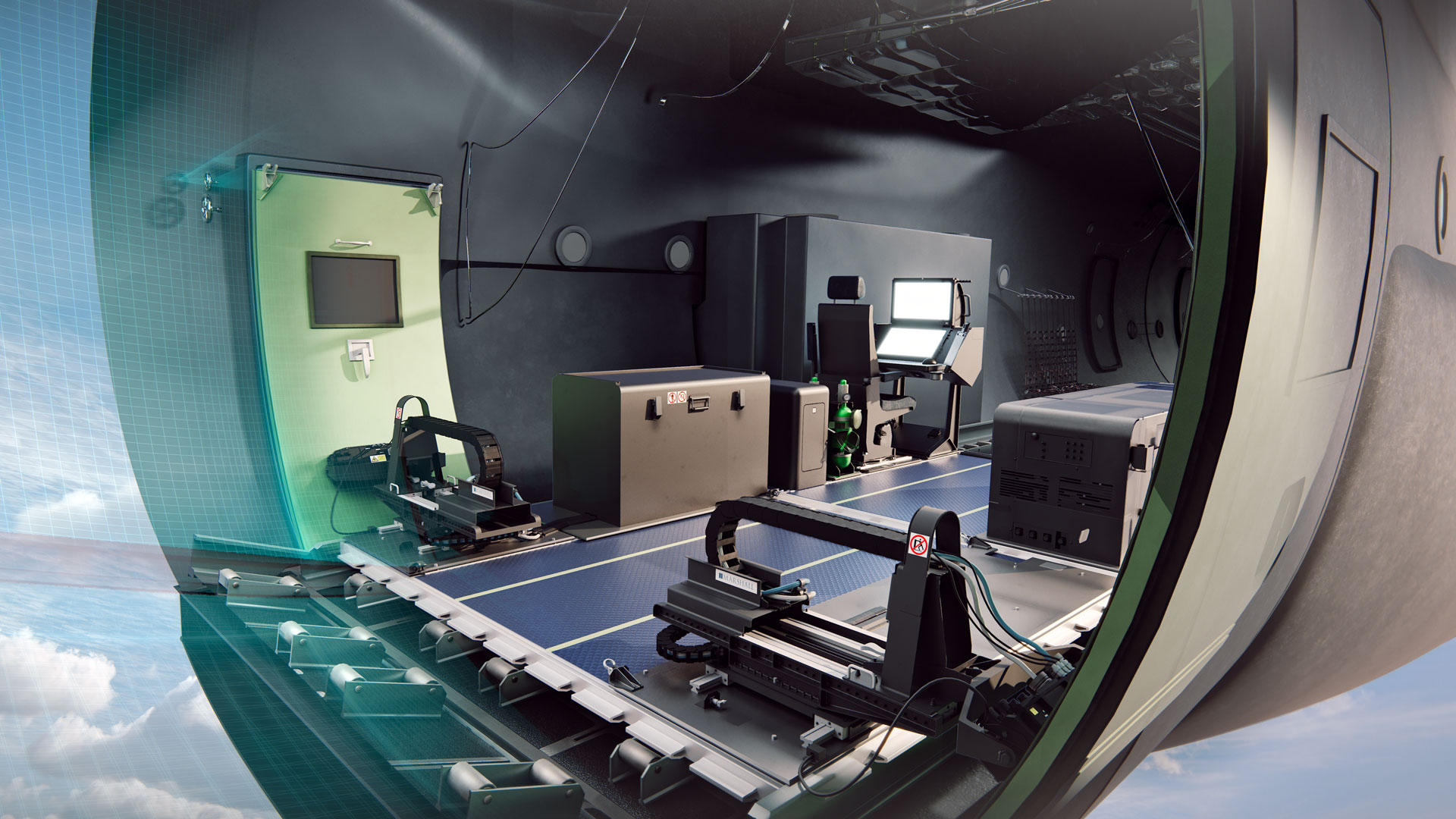

Marshall’s Adaptable Role-fit Capability (ARC) product family includes a range of platform-agnostic systems designed to rapidly enhance an aircraft’s capability within hours, enabling fleet operators to flexibly and efficiently reposition their aircraft for different types of mission - from cargo transport to medical evacuation and even intelligence, surveillance and reconnaissance (ISR).

Marshall ARC Radar is a modular sensor suite that allows operators of tactical transport aircraft to quickly and temporarily outfit an aircraft for intelligence, surveillance and reconnaissance (ISR) missions.

As the first of several products within the Marshall Adaptable Role-fit Capability (ARC) family, ARC Radar is a palletised solution with no permanent integration and no modifications required, utilising only existing aircraft power outlets.

The system’s potential applications are remarkably broad, ranging from military ISR land, sea or air missions to applied civilian operations such as search and rescue, humanitarian support, and disaster relief. Despite being fitted temporarily, the Osprey 30 radar suite maintains full performance during operation.

View the Marshall ARC-Radar spec sheet

Marshall ARC AMES enables fleet operators to outfit aircraft for tactical and strategic medical evacuation missions on demand, giving medium- and high-dependency patients the optimum chance of survival during air transport.

The palletised system can be rapidly installed and removed, requiring no modifications to the aircraft and utilising the existing aircraft power supply.

AMES can be configured to specific operational needs, while its modular design allows multiple modules to be connected to support additional patients.

Marshall’s roll-on, roll-off multiplatform cargo winch supports the loading of heavy objects - particularly in remote locations where ground support equipment is unavailable.

The system can be installed without any modifications, and makes use of existing electrical outlets for power, meaning it can easily be transferred as needed between multiple aircraft within a single fleet.

The Lockheed Martin C-130 Hercules remains the global tactical airlift platform of choice, having been in continuous production for longer than any other military aircraft in history. The airframe’s unmatched longevity is one of its hallmarks, with some aircraft built over 60 years ago still in operation today.

While operating a fleet of legacy C-130 aircraft is an extremely viable and cost-effective way to maintain tactical capability, maximising the lifespan of this legendary aircraft will require regular upgrades to ensure continued airworthiness and compliance with evolving aerospace regulations.

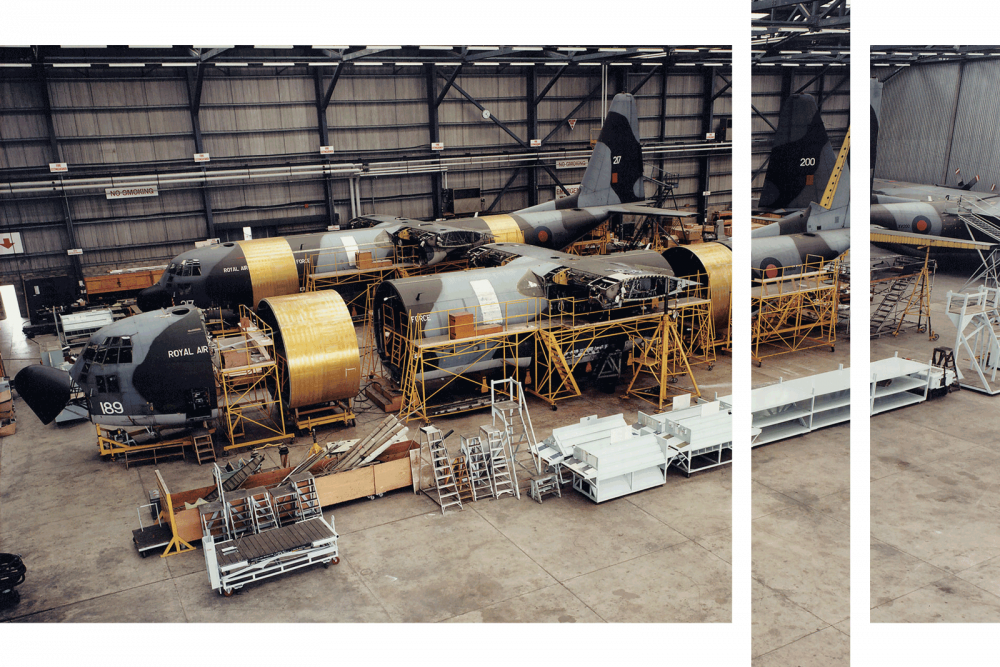

Marshall has an exceptional track record in delivering multi-year upgrade programmes designed to ensure that any C-130 aircraft can continue to support tactical operations around the world for many decades to come. We are also able to self-certify our own work, eliminating potential points of failure while ensuring we deliver a high-quality end-to-end solution for our customers.

Having replaced almost every major structural component on the C-130 without OEM involvement from Lockheed Martin, Marshall occupies a leading position in the non-standard repair and replacement market. We have even developed bespoke jacking and trestling instructions and equipment to allow significant structural items to be refurbished and replaced efficiently and to the highest standards.

Over the course of three years, Marshall performed an unprecedented fuselage stretch programme for the UK’s Royal Air Force (RAF). By adding two new fuselage sections to 29 C-130 aircraft, we were able to extend their total length by 15 feet and increase cargo compartment volume by roughly a third.

The OEM-supplied parts comprised a 100 inch plug for the front section of the aircraft, and an 80 inch section between the wing and the para troop doors. In addition to fitting the new sections into place, Marshall fully adapted the aircraft’s systems and wiring.

These aircraft flew for years and completed many vital missions, ferrying supplies and undertaking medevac sorties, among other duties.

The centre wing box is a fatigue-life item that will require replacement to ensure the continued airworthiness of the aircraft - no major C-130 structural component attracts such a high operational load.

Marshall is the world’s only maintenance, repair and overhaul organisation to have performed centre wing box replacement on both C-130K and C-130J aircraft - an exceptionally complex modification that can only be undertaken with dedicated facilities, tooling and knowhow.

Once the existing centre wing unit is removed, we install a zero life centre wing box kit - manufactured by Lockheed Martin - that delivers significant durability enhancements and provides service life extension for the centre wing box by up to three times longer than the original units.

Working in collaboration with Lockheed Martin, Marshall performs centre wing box replacement in a specially refurbished state-of-the-art hangar, harnessing our extensive C-130 deep maintenance and modification expertise, along with the use of lean processes, to remove and reinstall the new centre wing box as quickly and efficiently as possible.

Marshall has decades of expertise in avionics modernisation, overseeing comprehensive programmes from start to finish including design, installation, commissioning, testing and self-certifying.

We can perform avionics studies on any C-130 fleet, creating bespoke modernisation packages to address obsolescence, provide operational capability enhancements and ensure compliance with international aviation regulations. Our experienced test pilots work alongside a dedicated engineering team to evaluate the suitability and usability of all upgrades.

As part of one of Marshall’s most extensive and complex engineering projects to date, we undertook a comprehensive avionics upgrade for four legacy RNLAF aircraft, comprising a cockpit upgrade programme (CUP) and a cabin safety improvement programme (CSIMP).

To learn more about these broader projects and our comprehensive overhaul work for RNLAF.

Avionics modernisations we provide

In addition to conducting avionics modernisation programmes ourselves, we are able to provide third party organisations located near our customers with service bulletin kits containing all parts, components and instructions needed to perform the same modifications, while also training local technicians on the modification implementation process.

Learn more about our aviation skills and training offering.

Thanks to an exclusive agreement with QinetiQ, Marshall is the first company to certify and deliver the latest generation of lightweight armour (LAST Armor® LWA) for the C-130 Hercules, giving operators around the world confidence that their crews are protected against small arms fire in hostile environments.

The armour is manufactured from high tenacity polyethylene, making it extremely robust and remarkably light. It can be quickly and easily installed during scheduled maintenance or as a standalone activity, thus ensuring optimum aircraft mission availability.

“It was an easy decision to work together with Marshall Aerospace to certify and install the LAST Armor LWA onto our fleet of C-130Js. The level of protection provides a greater probability of mission success in harsh environments or potential conflicts and has promoted confidence in our aircrew.”

NATO Air Force representative

Marshall has decades of expertise in developing and providing solutions that extend the operating range of aircraft - whether through the production of auxiliary fuel tanks or the installation probes for aerial refuelling.

For over four decades, Marshall has produced auxiliary fuel tanks that have been retrofitted to 10 commercial and military aircraft types across five major OEMs including Airbus, Bombardier and Boeing. We offer a safe, reliable and certified solution needed to meet range-extension requirements, today and in the future.

We have been working extensively with Boeing since 1997, initially providing auxiliary fuel tanks for commercial airliner variants such as the 747-400ER and 777-220LR Worldliner. Since 2009, we have been Boeing’s exclusive supplier of auxiliary fuel tanks for the globally successful P-8 Poseidon maritime patrol aircraft, end customers for which include the United Kingdom, United states, Australia, India, New Zealand and Norway.

The auxiliary fuel tanks extend the flight range of the aircraft and allow for additional time on station. Marshall supplies the tanks in ship-sets of six, along with a number of components. With over 1,100 tanks produced to date, we have achieved an uninterrupted 100% on-time delivery record and 100% quality performance for over a decade.

The certified dual-wall aluminium honeycomb structure we use for our P-8 tanks is a cost-effective solution that maximises strength and reliability while also providing very competitive weight-to-fuel volume performance. Our tank designs offer a 15% increase in fuel volume compared to conventional bladder solutions, while also requiring less frequent maintenance.

We are constantly embedding continuous improvement into our processes and using of new materials such as composite solutions to expand the capabilities of our fuel tanks and systems.

Marshall has extensive experience providing fixed-mast receiver probes for aerial refuelling on a variety of civil and military aircraft types, including the Lockheed L1011 Tristar, Embraer 145, and Lockheed Martin C-130K Mk1/Mk3 and C-130J. These are simple, reliable additions to the aircraft with minimal maintenance requirements.

As the sole supplier of aerial refuelling probes for the C-130J, we carry out design, analysis and manufacturing in house, delivering completed probes – along with in-fuselage centre-wing connection kits – to Lockheed Martin’s final assembly line in Marietta. These probes are already installed on the Italian, Indian and Australian C-130J fleets, and can be supported on all non-US operated C-130J aircraft.

We can also design aerial refuelling probes to be removable, reducing drag and lowering the weight penalty when they are not needed.

We meet our through-life commitments with a Continued Airworthiness Management Programme that provides the evidence needed to underwrite safe operation throughout the life of a component or structure.

We have the experience and capability to produce, procure and test spares at both platform and system level, drawing on our in-house production expertise and mature global supply chain.

We can undertake all aspects of component repair and refurbishment, with all repairs designed to maintain airworthiness and structural integrity while reducing fatigue.

We manage the global supply chain for our products and the components we install, leveraging our long-term relationships with equipment and material OEMs to provide the required expertise at the right time in the right place.

Our supply chain processes are audited to AS9100 standard and our extensive knowledge of export regulations, including ITAR, helps ensure we maintain a compliant, sustainable and socially responsible procurement process.

We offer extensive warehouse and distribution services, including the capability to hold inventory in our fully bonded and climate-controlled storage space. Our warehouse team undertake all goods receipts, inspection, storage and handling of parts, including dangerous goods.

We are proud of our award-winning apprenticeship scheme that has enabled more than 21,000 people to launch their careers over the years, and are committed to leading the industry in addressing the severe global skills shortage.

Building on the strength of our reputation in this area, our dedicated education and training arm, Marshall Skills Academy, delivers apprenticeships for businesses across the defence and engineering sectors as well as in-house for Marshall. In addition to apprenticeships, we provide a comprehensive range of technical, regulatory and health and safety training programmes to civil and military customers.

To learn more about our skills and training offering, click here.